The Process Safety Questionnaire History

Process Safety is a disciplined framework for managing the integrity of operating systems and processes handling hazardous substances by applying good design principles, engineering, and operating practices. It deals with the prevention and control of incidents that have the potential to release hazardous materials or energy. Such incidents can cause toxic effects, fire, or explosion and could ultimately result in serious injuries, property damage, lost production, and environmental impact.

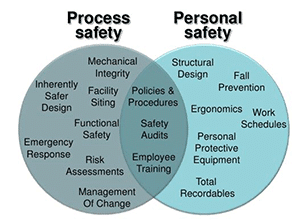

It was following several investigations into the BP Texas City disaster that greater attention began to be placed on the whole “process safety” question. Those investigations collectively concluded that BP had pretty good “personal safety” in place, but absolutely awful process safety measures. It was these system failures, at the process safety level, that were found to be amongst the most significant in the accident causation event chain.

The image clearly demonstrates the risk that businesses take by placing too great an emphasis on the personal safety side of the equation. Over the previous two decades, or so, we have seen an increasing focus on personal safety (often labelled as behavioural or BBS interventions). Transformational Safety® has long been recognized as an overt critic of the over-reliance on personal safety metrics. Even high hazard industries, such as petrochemical operations, still continue to make this error consistently.

The image clearly demonstrates the risk that businesses take by placing too great an emphasis on the personal safety side of the equation. Over the previous two decades, or so, we have seen an increasing focus on personal safety (often labelled as behavioural or BBS interventions). Transformational Safety® has long been recognized as an overt critic of the over-reliance on personal safety metrics. Even high hazard industries, such as petrochemical operations, still continue to make this error consistently.

On the day that the BP Deepwater Horizon blew up the senior executive team were on the rig celebrating seven years LTI free. At the moment they were cutting the cake eleven guys died. So what we see is the imbalance between process safety and personal safety has consistent toxic outcomes.

On the day that the BP Deepwater Horizon blew up the senior executive team were on the rig celebrating seven years LTI free. At the moment they were cutting the cake eleven guys died. So what we see is the imbalance between process safety and personal safety has consistent toxic outcomes.

In 2012 Transformationa lSafety was approached by a significant chemical manufacturer and presented with a challenge. This organization had implemented the Transformational Safety Culture methodology within their business. As a proactive safety aware leadership team they asked themselves a significant question

- “We now have a good idea where our safety culture and safety leadership competencies are placed – what about our process safety?”

This was, in effect, an excellent example of High Reliability thinking (without even knowing it).

The challenge put to Transformational Safety® was the design of a survey methodology that leveraged the power of the Transformational Safety® wireless survey technologies (and reporting protocols) in such a way that we could effectively analyse where a business might be, mapped against the Process Safety Model.

If you would like to take a look at the Transformational Safety Process Safety Questionnaire delivery strategies just click here.

If you would like to take a look at the Center for Chemical Process Safety’s take on Process Safety Culture just click here.

“Most organizations operate in failure states and that just remains invisible because bad stuff is not happening. We might call that the ‘normalization of deviance’ and, make no mistake, it will kill.”

Ricky, Atlanta

![]()

“I was fortunate to attend Transformational Safety’s Anatomies of Disaster Program. This was amongst the most powerful two days I have ever spent in a room. From the outset David Broadbent set the scene by dedicating the program to the late Rick Rescorla – the man who is credited with saving over 2700 lives on 9/11. Throughout the two days David would often respectively reflect and remember those who had died, or been injured, in the disasters we explored. He would say, and I will never forget, “…we must always remember those that lost their lives lift us up into the light of understanding”. I learnt so much. HRO, Resilience Engineering, Critical Incident Stress Management (CISM) and more. Those of us who were there are still talking about it…… Thankyou David